Triboelectric Generators Could Change the Future of Wearable Devices

What types of microgenerators can be worn on the body? Professor Chii-Rong Yang from the Department of Mechatronic Engineering at National Taiwan Normal University and his research team have made a significant breakthrough by integrating flexible electronics with triboelectric technology. They have successfully developed a self-powered wearable sensor. This advancement not only opens new avenues for research into energy-autonomous wearable electronics but also introduces novel directions and possibilities for future technological applications.

Professor Yang’s primary research areas include micro-electro-mechanical systems (MEMS), nanotechnology, emerging energy devices, and the synthesis of nanocarbon materials. He holds numerous domestic and international invention patents. Initially, his laboratory focused on research in solar and fuel cells. However, the energy-harvesting potential of triboelectric technology soon captured the team's interest. From early experiments using liquid metal electrodes to the later adoption of malleable metal electrodes, the team has continually sought materials and structural designs that offer enhanced functionality, performance, and safety.

The triboelectric generator (TEG) is a device capable of converting mechanical energy into electrical energy, making it well-suited for wearable technologies that require self-sustaining power sources. To meet the demand for high flexibility in wearable applications, Professor Yang’s team selected an innovative material that combines liquid metal with glaze powder. This composite not only maintains excellent electrical conductivity but also provides the flexibility and durability essential for wearable use. As the research progressed, and in response to the increasing performance demands of wearable systems, the team replaced conventional polymer substrates with textile-based materials. This shift further enhanced the triboelectric performance and device stability. Ultimately, they succeeded in developing a triboelectric device that is highly flexible, stable, cost-effective, and manufacturable through a simplified process.

Experimental tests demonstrated that this TEG, utilizing a GO@PDMS film treated with SF₆ plasma surface modification, was capable of generating an open-circuit voltage of 140.37 V and a short-circuit current of 2.57 μA. Under a load resistance of 50 MΩ, the device achieved a maximum output power of 130.5 μW. These results indicate a significant enhancement in energy conversion efficiency, highlighting the system’s potential for practical applications in self-powered wearable electronics.

Due to the triboelectric properties of PDMS, which tends toward negative charge generation, along with its ease of formulation and surface modification, the research team further engineered PDMS into a porous structure. By mixing graphene oxide (GO) flakes with deionized water to form a suspension, and blending it with PDMS slurry, they successfully fabricated a porous GO@PDMS triboelectric layer. This layer was then integrated with conductive fabric composed of 100% polyester electroplated with nickel and copper, resulting in a fabric-based triboelectric device characterized by high flexibility and softness. This configuration is particularly well-suited for integration with wearable electronic devices.

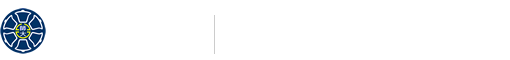

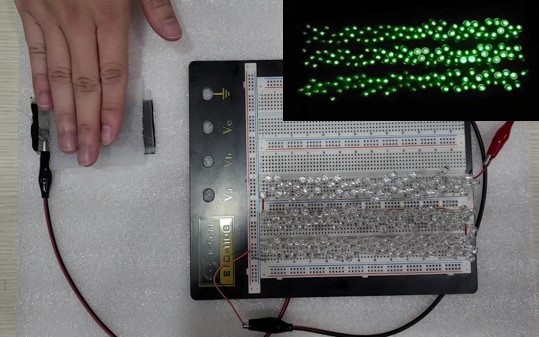

During the experiments, the research team integrated a TEG device into clothing and various parts of the body, successfully harvesting motion signals. Remarkably, the device was able to power 180 green LEDs connected in series, showcasing its potential as a micro-scale energy generator. Furthermore, the team demonstrated its application in wireless sensing by transmitting pressure signals to a computer via a Bluetooth module. According to Professor Yang, the triboelectric device also exhibits washability and long-term durability. When embedded in garments, it can function as a motion sensor, capturing human movement data for wearable sensing applications.

Professor Yang noted that beyond energy generation, the device also functions effectively as a pressure sensor capable of monitoring human motion and physiological signals. For instance, when embedded in footwear, it can emit light with each step; when integrated into clothing, it can continuously monitor heart rate. In critical situations such as cardiac arrest, the system could instantly alert emergency services or trigger automatic hospital notifications, thereby maximizing the chances of timely medical intervention during the golden rescue timing.

This research has also involved collaboration with the Department of Electrical Engineering, where the sensor was integrated into a robotic arm. Upon detecting contact signals, the system was able to immediately cut power to the arm—functioning like an "electronic skin" that enhances the safety of robotic systems by enabling rapid response and providing crucial escape time in emergency scenarios. Beyond everyday energy harvesting, this technology also shows promise in specialized environments, such as integration into life vests, where it can ensure both safety monitoring and continuous power supply in critical situations.

Looking ahead, Professor Yang emphasized that the team is currently working on integrating capacitors with triboelectric generators, aiming to enable energy storage within the system itself. This innovation is expected to significantly expand the application potential of fabric-based triboelectric devices. In the era of the Internet of Things (IoT), where sensors are required in virtually every environment, reliance on conventional batteries becomes impractical. By allowing sensors to harvest mechanical energy and convert it into electricity through triboelectric generators, this technology offers a promising solution for sustainable, maintenance-free sensing systems—paving the way for broader deployment and functionality in the IoT application field.

Figure 1: LED bulbs illuminated by a TEG

Figure 2: Wireless transmission of pressure sensing data using a TEG

Figure 3: Application of TEG as "electronic skin" for a robotic arm

Yang, C. R., Ko, C. T., Chang, S. F., & Huang, M. J. (2022). Study on fabric-based triboelectric nanogenerator using graphene oxide/porous PDMS as a compound friction layer. Nano Energy, 92, Article 106791. https://doi.org/10.1016/j.nanoen.2021.106791

Chii-Rong Yang Professor | Department of Mechatronic Engineering

Professor Chii-Rong Yang earned his Ph.D. in Mechanical Engineering from National Sun Yat-sen University in 1996. His primary research interests include micro-electro-mechanical systems (MEMS), nanotechnology, emerging energy devices, and the synthesis of nanocarbon materials. Since 2010, he has published over 30 international SCI journal papers and holds numerous domestic and international patents. He also serves as a reviewer for the Ministry of Economic Affairs' SBIR program and as a peer reviewer for more than ten international SCI journals.